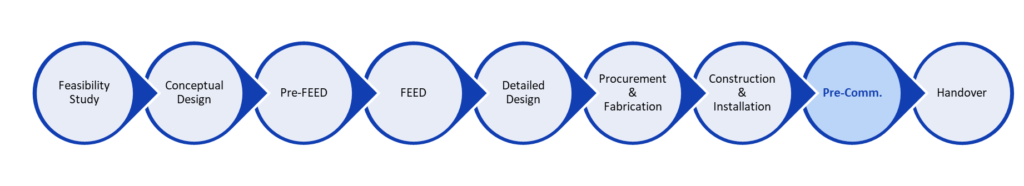

This article is part of a series about the typical stages and phases of complex engineering projects. Each article takes one stage and describes how Assai supports the requirements and common challenges of that stage – ultimately contributing to the efficient, timely, (cost-)effective and safe delivery of projects.

Download all articles on complex engineering stages in a 50+ page PDF

(Pre-)Commissioning in a nutshell

The pre-commissioning (or pre-comm) stage of engineering projects is a critical phase that occurs after construction & installation and before the facility/asset is put into operation. It involves both the contractor and the operator.

Pre-commissioning aims to ensure that the facility is ready for safe and efficient operation and to identify and resolve any issues that may have arisen during construction. It involves a series of activities that aim to ensure that all systems and components of the facility are properly installed, tested, and prepared for the Operations phase (see next section).

After pre-commissioning follows commissioning, the main difference is that during pre-commissioning, dry runs and trial runs with test fluids (e.g. water) may occur. Still, during commissioning, actual process fluids are introduced to process equipment. So both may involve testing control systems, starting up equipment, and conducting trial runs. After all required pre-commissioning and commissioning checks have been passed successfully, start-up (SU) can take place with a handover from the engineering project to Operations.

What happens during Pre-Commissioning?

Firstly, Mechanical Completion (MC) verification is an important interface between construction and pre-commissioning. This can stand on its own or be part of pre-commissioning. MC verification confirms that the construction and installation of all components (e.g. equipment, piping, cabling, electrical and mechanical components, instrumentation) are physically complete, inspected, tested, and have all required documentation. This results in a Mechanical Completion Certificate (MCS).

Other typical activities during pre-commissioning include:

- Flushing and cleaning of systems: the piping and process systems need to be cleared of any debris or contaminants that may have been introduced during construction.

- Leak testing: all piping and equipment are tested to ensure there are no leaks or other issues that could cause problems during operations.

- Testing of safety systems: safety systems, such as fire protection and emergency shutdown systems, are tested to ensure they function properly.

- Testing of control systems: control systems, such as SCADA (Supervisory Control and Data Acquisition) systems, DCS (Distributed Control Systems), and PLC (Programmable Logic Controller), are tested to ensure they are properly configured and able to control and monitor the various systems and equipment in the facility.

- Commissioning of utilities: utilities, such as electricity, water, and gas, are commissioned to ensure that they are available and functioning properly.

- Training of personnel: training people on the operation and maintenance of the facility.

(Pre-)commissioning checks & checklists

As mentioned, (pre-)commissioning involves many checks on many different components. Organizing checkpoints into checklists helps engineers or other specialists efficiently, correctly, safely, and timely completion of all required checks. If there are follow-up actions or open ends, punch lists may be needed to keep track of any remaining items to close a checkpoint.

All the activities mentioned earlier can be supported by (pre-)commissioning checklists. Individual systems or equipment (types) may also have their own (detailed) checklists to check if they are functioning properly.

Some example checkpoints to illustrate:

- Visually check equipment for defects.

- Ensure correct equipment assembly based on the vendor P&ID drawing.

- Equipment grounding is properly installed.

- Access ladders are properly fitted and fastened.

- Remove all temporary construction materials.

- Operating blinds are installed as in the drawing.

- Platforms allow safe access to valves and instrumentation on the skid.

- Pressure Safety Valves (PSV) inlet and outlet open; by-pass valves closed.

- Check all drain and vent valves.

How Assai supports Pre-Commissioning

Assai provides out-of-the-box functionality for all project stages (and operations), based on more than 30 years of experience. Key Assai features supporting Pre-Commissioning and Commissioning include:

- Easy access to the latest project documentation for all stakeholders

- Checklist module: flexible, unlimited checks, grouped as checklists and automatically assigned to systems or equipment

- Distinguish between mandatory and optional checks

- Complete checklists on-site on a tablet, with Assai Mobile

- Create (upload) and complete punch lists online

- Asset Management module with asset hierarchy and commissioning stages

- Restrict commissioning stage changes for components if mandatory checks are pending

- Technical query module to process any type of request, deviation, or issue, also on-site with Assai Mobile

- Find documentation and technical queries by system, unit, tag, or equipment

- Dedicated reports on (pre-)commissioning progress. See bottlenecks before they become a problem or cause delays.

- Advanced reporting capabilities with Power BI (and integrated reports)

- Comprehensive REST API library to interface with other applications

Plus, as seen in previous articles:

- Assai offers a proven, specialized, user-friendly and secure eDMS for all project deliverables, no matter the project size or complexity. Everything is traceable and can be reported on.

- Assai Cloud (or on-premises) is a flexible, turnkey solution with out-of-the-box support for engineering projects from start to end, plus operations, maintenance & modifications, and Digital Twin environments.

Summary

We hope you found this article about the Pre-Commissioning stage interesting and useful. Please let us know if you have any questions or feedback, or if you would like to explore how Assai could support your project(s).

A short summary of what was discussed in this article:

- Pre-commissioning and commissioning occur after construction and installation, and before the facility or asset is put into operation.

- (Pre-)commissioning involves various activities to ensure all systems and components of the facility are properly installed, tested, and ready for operation. This can require checklists and punch lists.

- Assai offers special checklist functionality and much more to support the efficient, timely, and safe completion of (pre-)commissioning.

- Many industry leaders worldwide trust Assai as their eDMS solution of choice, which is based on 30+ years of industry experience and best practices. Assai promises (and delivers) true out-of-the-box support for all project stages, including Pre-commissioning and Commissioning, as well as for operations, maintenance & modifications, and Digital Twins.

Download the 50+ page PDF!

If you would like to read all articles in a 50+ page PDF which you can print or distribute in your organization, you can download them via the form below:

Previous stage: Construction & Installation

All articles in this series:

Feasibility Study

Conceptual Design

Pre-FEED

FEED

Detailed Design

Procurement & Fabrication

Construction & Installation

Pre-Commissioning (current article)

Handover

Want to explore more about Document Management and Document Control? Download our latest whitepaper and guide via the buttons below!

Whitepaper: What to consider when purchasing a DMS

The definitive guide to document control and document management