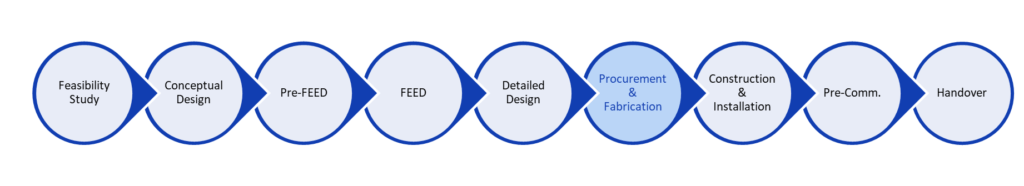

This article is part of a series about the typical stages and phases of complex engineering projects. Each article takes one stage and describes how Assai supports the requirements and common challenges of that stage – ultimately contributing to the efficient, timely, (cost-)effective and safe delivery of projects.

Download all articles on complex engineering stages in a 50+ page PDF

Procurement & Fabrication in a nutshell

After successful completion of the Detailed Design stage, procurement and fabrication come next. This happens based on the final, approved design documents and “Approved for Construction (AFC)” drawings.

Procurement involves the acquisition of materials, equipment, and services needed for construction. This may include activities such as identifying vendors, requesting bids or proposals (bidding & tendering), and negotiating contracts. Sometimes preferred suppliers have been listed upfront.

Fabrication, on the other hand, involves the actual manufacturing or assembly of materials and components into finished products, which can be put together on-site. This can involve cutting and shaping materials, welding and assembling parts, and testing the finished product to ensure that it meets the required specifications. Together, procurement and fabrication are crucial steps in the successful completion of any engineering project.

Who is involved in Procurement & Fabrication?

Procurement and fabrication are usually carried out by different teams or departments. The procurement team is responsible for acquiring the materials and services needed for the project, while the fabrication team is responsible for ensuring that the materials are manufactured or assembled according to the project specifications.

In some cases, the same company or organization may be responsible for both procurement and fabrication. For example, a construction company may have its own procurement team that acquires materials from suppliers, and a fabrication team that assembles those materials into finished products. In other cases, the procurement and fabrication processes may be carried out by separate companies. For example, a construction company may hire a subcontractor to fabricate certain components of a project.

Overall, the key players involved in procurement and fabrication include the project owner or client (providing the overall direction and funding for the project), the engineering design team, procurement teams, fabrication teams, and vendors or suppliers of materials and services. Also involved may be consultants who provide advice and expertise on procurement and fabrication, and regulators or government agencies responsible for overseeing the procurement process.

Typical challenges for Procurement & Fabrication

Challenges for procurement include identifying and sourcing the right materials and equipment for the project, negotiating contracts with suppliers, and ensuring that all materials and equipment are delivered on time and within budget. Another challenge can be coordinating the work of different vendors or contractors, as well as managing any changes to the project scope that may affect the procurement of materials and equipment. Furthermore, there can be challenges related to document control, such as ensuring that all project documentation is accurate, up-to-date and easily accessible to all stakeholders.

Challenges for fabrication include coordinating the fabrication of many different components, ensuring that all work is completed on time and within budget, and managing changes to the project scope that may affect the fabrication process. The same document control challenges as for procurement apply here as well. Other potential challenges include managing the work of different contractors or vendors, and ensuring that all work is done in accordance with relevant safety and quality standards. Furthermore, there may be challenges related to the logistics of transporting and assembling fabricated components on site.

How Assai supports Procurement & Fabrication

The cutting-edge document control system Assai helps to ensure that all project documentation is accurate, up-to-date, and easily accessible to all team members and stakeholders. This is particularly important for procurement to source and purchase the right materials and equipment, or to provide fabrication with the right drawings and instructions. Assai also streamlines communication and collaboration among team members, and provides a centralized location for storing and organizing all project documentation. This reduces the risk of errors and delays for the project.

Key Assai features that support Procurement & Fabrication:

- Central repository for all relevant documents and drawings

- Organize documents in packages and (custom) folder trees

- Vendor document control module (SDRL / VDRL tracking)

- Assai breakdown structure to quickly find documentation by tag or equipment

- Assai Portal to exchange documents and drawings with vendors and contractors

- Technical Queries module to process any kinds of requests or deviations

- Correspondence module to manage official letters and communications

- Integration options with procurement systems (using REST API)

- Power BI reporting integration

Plus, as seen in previous articles:

- Assai offers a proven, specialized, user-friendly and secure eDMS for all project deliverables, no matter the project size or complexity. Everything is traceable and can be reported on.

- Assai Cloud (or on-premises) is a flexible, turnkey solution with out-of-the-box support for engineering projects from start to end, plus operations, maintenance & modifications, and Digital Twin environments.

Summary

We hope you found this article about the Procurement & Fabrication stage interesting and useful. Please let us know if you have any questions or feedback, or if you would like to explore with us how Assai could support your project(s).

A short summary of what was discussed in this article:

- The Detailed Design stage is followed by procurement and fabrication.

- Procurement involves acquiring materials and equipment for construction, while fabrication involves manufacturing and assembling materials into finished products.

- Just like in the preceding design stages of the project, a specialised eDMS system and Document Control function are important assets to successfully execute procurement and fabrication – efficiently, safely, on time and within budget.

- Many industry leaders worldwide trust Assai as their eDMS solution of choice, which is based on 30+ years of industry experience and best practices. Assai promises (and delivers) true out-of-the-box support for all project stages including Procurement & Fabrication, as well as for operations, maintenance & modifications, and Digital Twins.

Download the 50+ page PDF!

If you would like to read all articles in a 50+ page PDF which you can print or distribute in your organization, you can download them via the form below:

Previous stage: Detailed Design

Next stage: Construction & Installation

All articles in this series:

Feasibility Study

Conceptual Design

Pre-FEED

FEED

Detailed Design

Procurement & Fabrication (current article)

Construction & Installation

Pre-commissioning

Handover

Want to explore more about Document Management and Document Control? Download our latest whitepaper and guide via the buttons below!

Whitepaper: What to consider when purchasing a DMSThe definitive guide to document control and document management